Research & Innovation | 05/01/2026

Alongside the Hyvolution trade fair, a key event for the hydrogen industry, Lab Crigen, one of ENGIE Group’s Research...

Emerging Techs | 14/11/2025

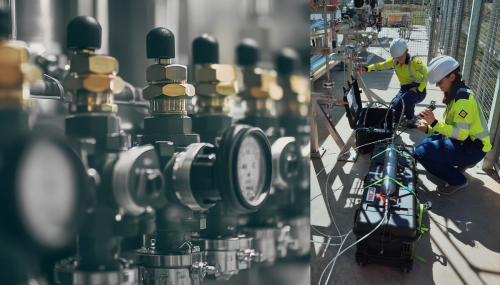

The MultiPLHY demonstrator project, conducted in partnership with Neste, Sunfire, the CEA and ENGIE to produce...

Emerging Techs | 13/11/2025

In this iScience paper, the ENGIEs Scientific Council, examines how energy and chemistry can converge to a decarbonized...