We support multiple projects for the development of methanation, gasification, biogas, hydrogen, and energy storage technologies.

CFD modelling is a digital modelling technique that allows physical and chemical processes to be simulated from lab-scale to industrial applications. It can be used to test a technology, understand physical or (bio)chemical phenomena, validate a business plan, test possible modifications in the design of an installation, acquire data that cannot be measured physically, identify potential causes of incidents, and much more.

In line with ENGIE’s innovation and energy transition strategy, CFD modelling is increasingly being used in a lot of the group’s R&I initiatives, from the lowest to the highest technology readiness level.

Multiple ENGIE R&I projects have called upon the Lab CRIGEN CFD team’s expertise. A prime example is the Ambher project which aims to develop technologies for short and long-term hydrogen storage. Multiple reactors with Periodic Open Cellular Structures (POCs) were defined and modelled, allowing a trade-off between pressure drop and heat transfer performances for the design of an optimal reactor.

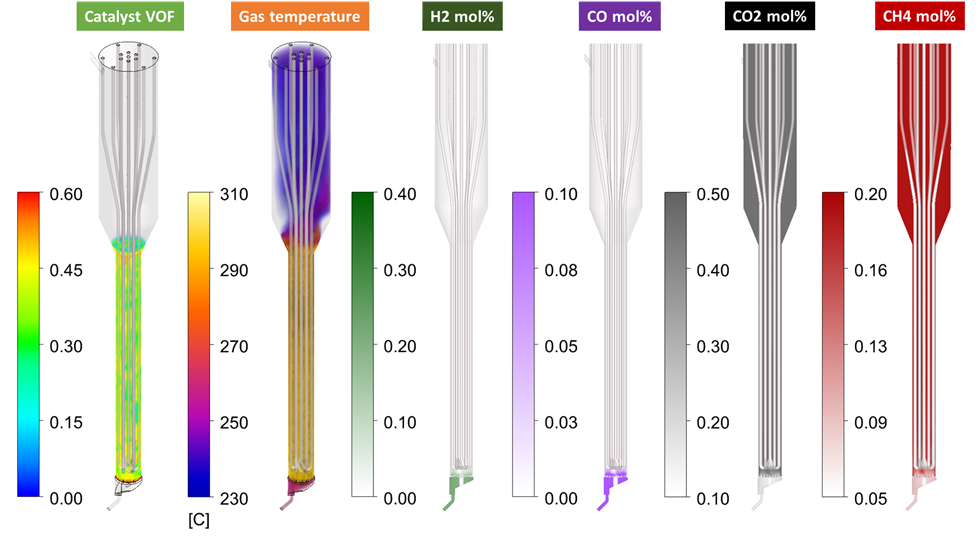

For the Gaya platform, the virtual model of the methanation reactor was extended to various operating conditions for CO and CO2 methanation. Subsequently, reactor performance figures (hydrodynamics, thermal performance, and conversion rates) were calculated using the model and compared with data obtained from the real-world reactor. The results were very much in line, meaning that the model can be considered complete and ready for investigations at industrial scale. In parallel, a CFD modeling of the Gaya gasification reactor was developed and validated for pine wood gasification. This virtual model is now ready for scale-up and extension to various biomass feedstocks.

Many more projects have been supported by the CFD team in areas of biomethane production (optimization of the bioreactor), liquid hydrogen storage (assessment of the self-pressurization of the tank), biogas purification (assessment of CO2 purification with lime in the Picachaux bubble column reactor) and industrial hydrogen combustion (development of a new hydrogen combustion modeling for the assessment of pollutant emissions and flame features).

Multiple support activities are planned in 2024. Team manager Nicolas Meynet gives an indication of the scope: “We support multiple projects for the development of methanation, gasification, biogas, hydrogen, and energy storage technologies. We also provide operational performance support. And we run a techno-watch program about granular flows modeling to keep track with innovations.”

Lab Crigen CFD Team

Contact: Nicolas Meynet, CFD Team Manager

Ambher membrane reactor with Periodic Open Cellular Structures (POCs)

Contact: Assia Saker, Ambher Project Leader

Website: https://www.ambherproject.eu/

Gaya methanation reactor (fluidized bed, temperature, gas mixture)

Contact: Marion Maheut, Gaya Project Leader