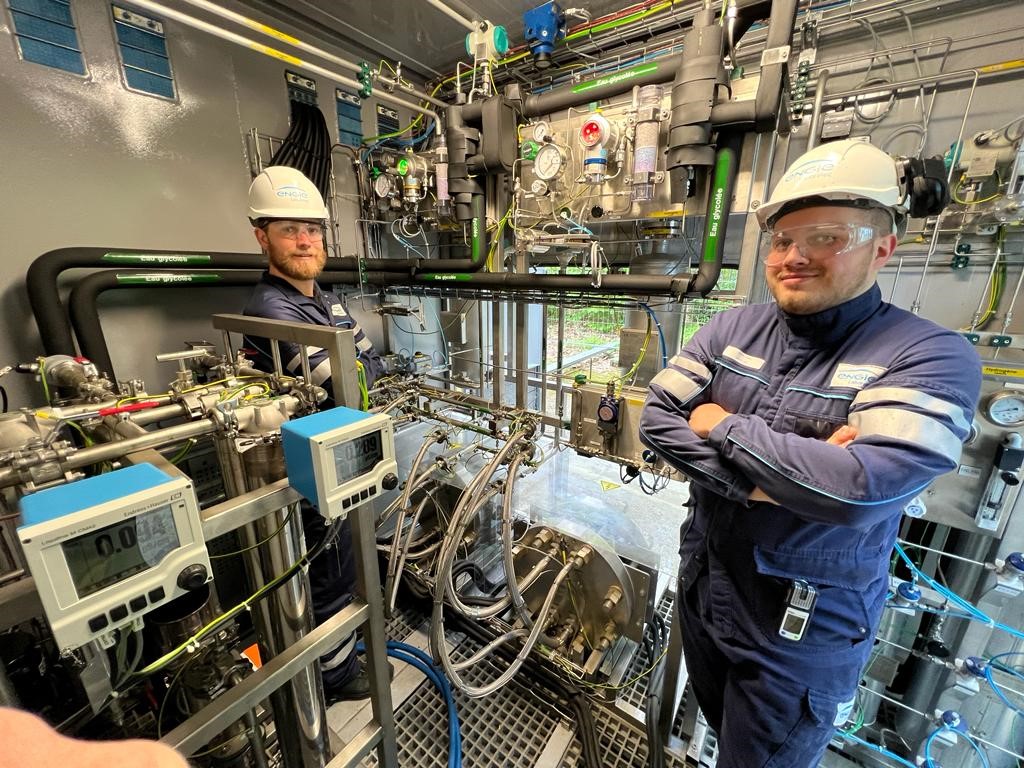

The equipment commissioned comprises a 50-kWe Proton Exchange Membrane (PEM) electrolyser, producing up to 10 Nm³/h of green hydrogen. Next to the pilot scale electrolyser, Laborelec has also commissioned a lab-scale installation to test the impact of the water quality on the electrolysis process at the cell level in summer 2023. The electrolyser is equipped with various sensors and a digital interface. It can be shared with other ENGIE R&I centres, allowing tests to be carried out on power quality, grid integration, interaction with other generation units, and more. Research projects will be carried out in close collaboration with Lab Crigen’s H2 Factory to support ENGIE’s R&I roadmap.

In 2022, an initial measurement campaign was carried out to test the equipment’s compliance with power quality standards, principally EN 50160. Power quality measurements with high-sampling recording devices revealed that significant perturbations were induced in the grid, leading to non-compliance with engineering standards such as IEEE519.

Laborelec expert outlines the importance of such test campaigns for ENGIE: “In major projects involving large-scale H2 electrolysers such as HyNetherlands and Columbus, it’s essential to carefully evaluate the specification and performance of the rectifier to be purchased. We recommend that preliminary lab-scale tests should be carried out.”

For additional analysis purposes, an electrical simulation model was developed, validated by measuring.

The research continues with further tests on various types of power converters, including an innovative topology with low-harmonic emissions developed in a consortium with industrial and academic partners. The potential impact of low-quality power grids on electrolyser performance will also be studied.